Inspection services play an important role in providing assurance of the operational safety of many items which are used in everyday life. Accreditation demonstrates the technical competence of organizations to perform inspections of products, services, processes, installations and design.

Accreditation recognizes competence against national and international standards which allows inspections reports to be more acceptable for overseas and domestic markets. Inspection bodies can be accredited once and accepted anywhere to improve their competitiveness.

Examples of inspection activity include;

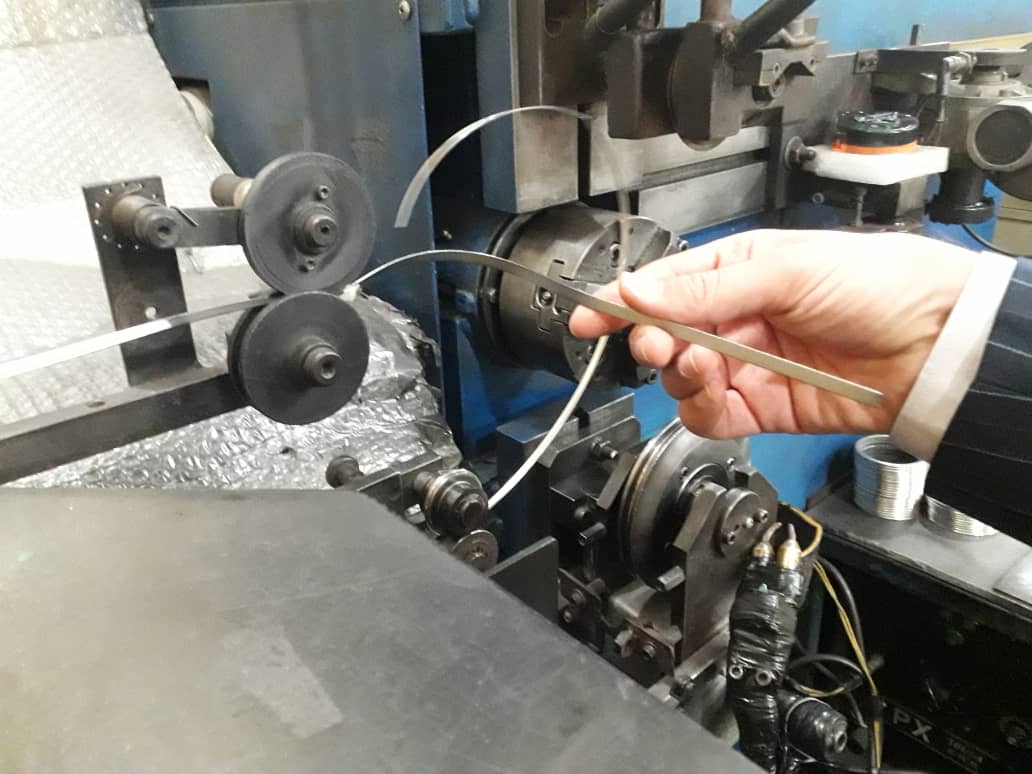

- Engineering Inspection (including manufacture of boilers / pressure vessels, welding inspections, petroleum and gas equipment)

What are the benefits of a First Article Inspection?

- Preventing miscommunication and solving problems

- Your requirements/standards are understood

- Certainty in terms of the use of the right materials / designs / dimensions / colours, etc.

- Implement improvements for the mass production

- Prevent additional costs and delays

- Effective start for the expected result

What are the benefits of a During Production Inspection?

- Discovering and resolving complications in good time

- Intervention to prevent delays

- Maintaining quality at the right level

What are the benefits of a Pre-Shipment Inspection / Final Random Inspection?

- Extensive inspection report for both internal and external use / support

- Overview of any shortcomings

- No surprises and uncertainty

- Decisions can be taken on the basis of the report regarding subsequent actions

(for example: not shipping, production again from scratch, part shipment, discuss new price, etc.) - Preventing risks relating to costs and delays

- Demonstrating to your supplier and clients that you place great value on quality

Certainty of quality